Introduction

Optical particle sensors are being widely deployed in outdoor and indoor applications to monitor air quality and control air cleaning technologies. Low-cost sensors are not designed to replace expensive reference instruments but are being widely adopted in a range of applications with 57M units shipped last year. There are many studies discussing the limitations of these devices especially for indoor sources[1]. The EPA cautions that their data are ‘estimates’ and not a substitute for expensive reference devices. They all use similar low-cost electronics. Seeing a better way, Piera leveraged advances in semiconductors, Machine Learning/AI and an increasing understanding of the health threat created by sub-micron particles to create a new generation of Intelligent Particle Sensors (IPS) with more accurate, complete data on particle size and count which can identify likely sources of pollution. This data driven approach in a real-time monitor provides insight and enables actions to be taken to reduce or remove particle sources and improve air quality. Achieving this in a low-cost device required a ‘correct by construction’ technology stack including a revolutionary ASIC, calibration algorithms and methodologies, and highly scalable test and QA processes. Piera’s devices are calibrated based on particle count and size, unlike all other low-cost sensor manufacturers that utilize Mass Concentration (MC or PM). This enables IPS to meet the ISO 21501-4 standard for calibration of optical sensors. ISO 21501-4 compliance is a requirement for monitoring clean rooms under ISO 14244-1. Piera’s IPS is the first low-cost sensor to achieve this certification.

The ISO 21501-4 Standard

The International Organization for Standardization (ISO), introduced ISO 21501 in 2007… “to provide a calibration procedure and verification method for particle counters, so as to minimize the inaccuracy in the measurement result by a counter, as well as the difference in the results measured by different instruments.” The 2015 publication includes 4 different sections with each dedicated to a specific particle counting technology/application. Part 4 (-4): Light Scattering Airborne Particle Counter for Clean Spaces applies to Light Scattering Aerosol Particle Counters (LSAPC). Piera’s IPS is an LSAPC. The ISO14644-1 standard for clean rooms requires monitoring with instruments calibrated to ISO 21501-4. Certification to ISO 21501-4 can be done by any company following strict testing requirements. Piera has utilized a third-party testing lab, The Korea Electronics Technology Institute (KETI) for its certification.

Following the testing protocol specified in ISO 21501-4, KETI tested 4 IPS sensors from a standard production run utilizing a controlled chamber and PSL particles of sizes 0.3, 0.5, 1.0 microns traceable to NIST. A flow meter monitored air flow and a reference instrument (Grimm 11-D) calibrated to ISO 21501-4 was compared to the ISP sensors. During the test period, Counting Efficiency and Flow rate were measured for each of the 3 particle sizes. Key metrics reported include Average of Fine dust (#/m2), False count rate (#/m2), counting efficiency (%), uncertainty (%), Flow rate (L/min). ISO 21501-4 mandates counting efficiency within 10% of the reference device which was met for all devices at all sizes. Copies of the certification document and test report are available upon request.

Applications that benefit from ISO 21501-4 certified sensors and instruments include hospitals, healthcare facilities, electronic and semiconductor manufacturing facilities, pharmaceutical and other industrial workplaces. Piera’s Canāree Air Quality Monitors are the first affordable devices that have a ‘clean room’ quality sensor.

Certifications and Standards for measuring air quality

The Clean Air Act requires the EPA to set National Ambient Air Quality Standards (NAAQS) for pollutants that are common in outdoor air. The WHO has similar standards but at a much lower level and in Sept 2021, WHO reduced the daily value for PM 2.5 in half to 5.0ug (the US is still at 12.5 ug but this is under review). PM is short for Mass Concentration (MC or PM) the weight of all the particles (ug or micrograms) 2.5 microns and below. MC is not used to measure air quality when it’s made up of smaller particles. Instead, particle count and size are needed as in ISO 21501-4. The current generation of low-cost sensors are calibrated to MC since that is what the EPA mandates and are not able to reliably measure below 10 ug, especially in environments where submicron particles are dominant (indoors).

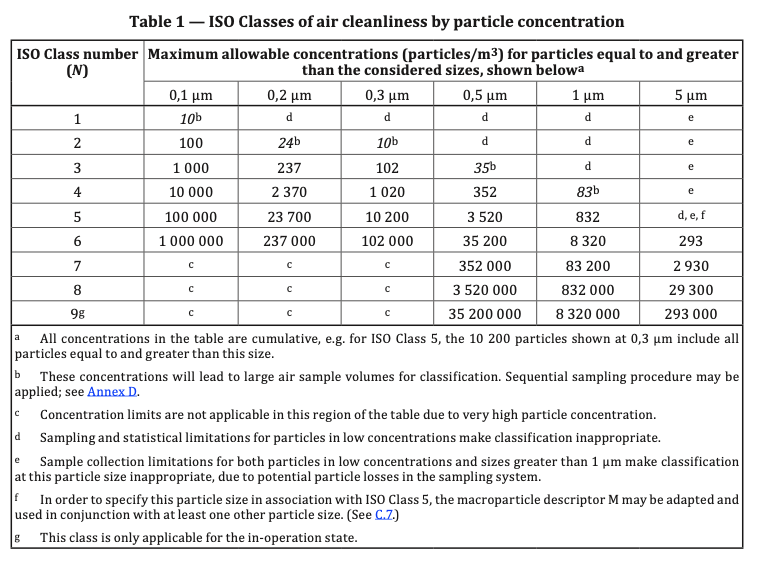

There are no equivalent standards for Indoor Air Quality. Since ISO 14244-1 is already used indoors and measures particles of sizes 0.1, 0.3, 0.5 and 1.0 microns it should be considered. In fact, Class 9 is considered ‘Normal’ or good air, see Table 1.

Instead, several third party indoor ‘standards and certifications’ have emerged based on MC. These include ASHRAE Standard 62.1, ASTM-D8405-21, MCERTS (UK). In the built environment RESET, WELL, LEEDS have developed their own audit and compliance standards.

Regardless of what standard is used a common requirement is the need to have a methodology for calibration. ISO 21501-4 is the recognized standard for optical particle counter calibration.

Summary

Piera’s custom PSC-1 processor with 3 US patents is the foundation of our IPS Sensor and Canāree AQMs. Representing years of development and leveraging advanced semiconductor processes it delivers accurate and precise data on particle size and count across a wide range of particle sizes for all our devices. It’s the basis of our ‘correct by construction’ technology stack and investments in calibration and testing ensuring every device meets specifications and allows customers to use them with confidence.

You might not need your home, office, or public space to be a class 6 ‘clean room’, but you do want the air to be good enough not to affect your health. This requires the type of data delivered by Piera.

[1] Response of consumer and research grade indoor air quality monitors to residential sources of fine particles, Singer, Delp https://pubmed.ncbi.nlm.nih.gov/29683219/